In this article:

The once forgotten boring walls and ceilings painted by ordinary paint are inferior to modern wallpaper, stretch ceilings and trimming of drywall. However, despite the current trend, the volumes of water-produced paint (which is often called water-dispersion), continue to grow stably. Moreover, such a production is considered cost-effective and cost-effective, since in this segment of paintwork products simply lacks tough competition.

We draw up documents

Water-emulsion paints - This is a suspension, which consists of water, binding the foundation and pigments. All initial raw materials are almost harmless to the human body, since there are no harmful evaporation. That is why the certificate of conformity for paint is not necessary, since the water-level paint is not in the list of paints and varnishes, which is subject to mandatory certification. A voluntary certificate of conformity should be issued on the waterfront paint (Certificate photo).

It is issued for any kind of paint products, and it can be obtained in an accredited certification body. Before starting production activities, a beginner entrepreneur must examine the regulatory documents regulating the quality of finished products, namely:

- GOST 19214-80 Paints Water-emulsion for internal works. Technical conditions

- GOST 20833-75 Water-emulsion paints for outdoor work. Technical conditions

We should not forget about the official design of the business, namely, registration of a legal entity (or physical) person. To do this, determine the most preferred option, making the minimum tax deductions. For example, this may be LLC (with a simplified form of taxation) or an individual entrepreneur.

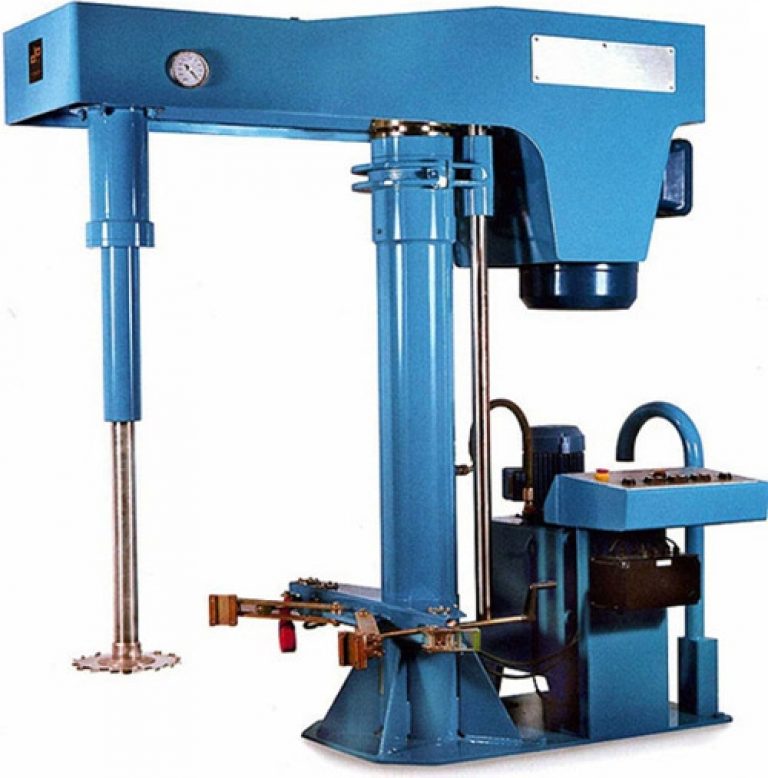

Required equipment for the production of waterfront paint

The technological line will consist of the following equipment:

- dissolver;

- bead mill;

- automatic filling line and packaging of finished products.

Dissolver - This is a special unit intended for mechanical mixing of all source components. Thanks to the rapid rotation of the dispersion disk with the teeth, the particle growing efficiency is ensured: they encounter, mixed, grind and dissolve. The dissolver is equipped with a high-speed stirring of the milling type, and the rotational speed can be adjusted. Due to this, you can most optimally organize the production process.

If necessary, for convenience, this equipment can be equipped with a lift (hydraulic or pneumatic).

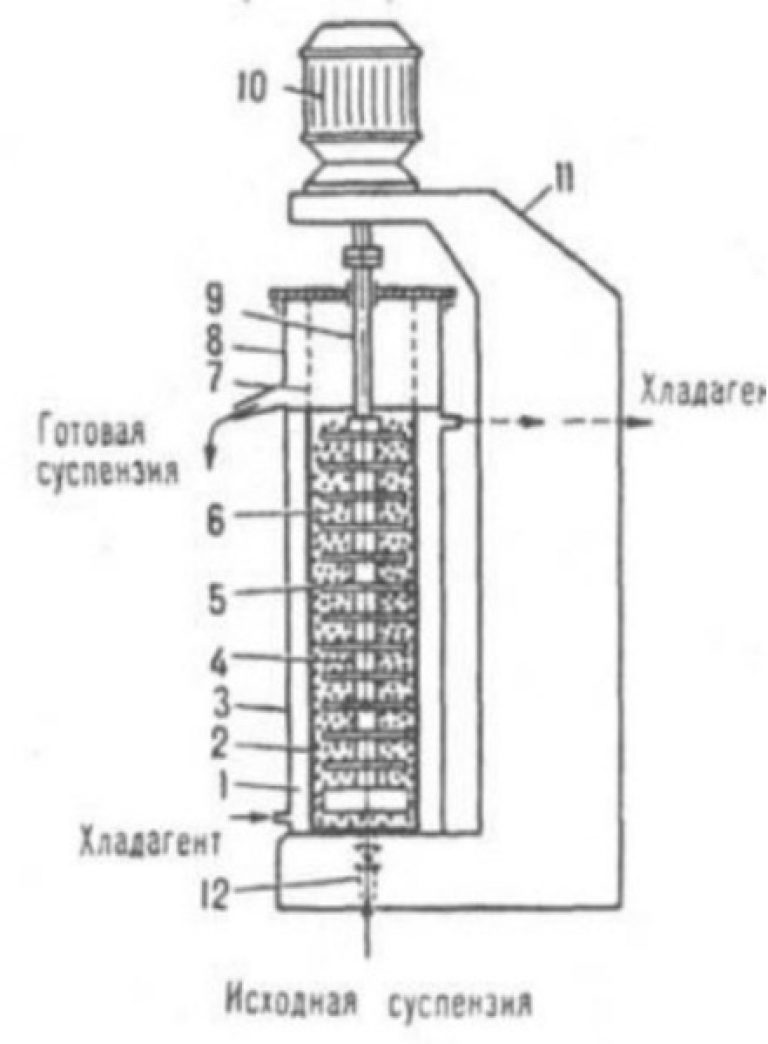

When using the Dissolver, service period bead Mill significantly increases. The main function of the bead mill is homogenization of all components for the manufacture of future paint. It is characterized by high performance, because several disks provide high-quality processing of raw materials. The housing of the bead mill and sieve are made of durable metal, which does not rust and not wear out. The graininess is easily adjustable by changing the dimensions of the fraction.

The automatic packaging line consists of the following key mechanisms:

- conveyor belt with cylindrical capacities;

- system of feeding of tanks;

- caps of covers;

- storage.

Components of water-emulsion paint

About 10-15 components are often part of the water-level paint, which is in the percentage ratio:

- latex dispersion (about 40%);

- pigments and fillers (37%);

- plasticizer (3%);

- functional additives: cellulose ether, titanium dioxide, etc. (nine%);

- mel is fine (11%).

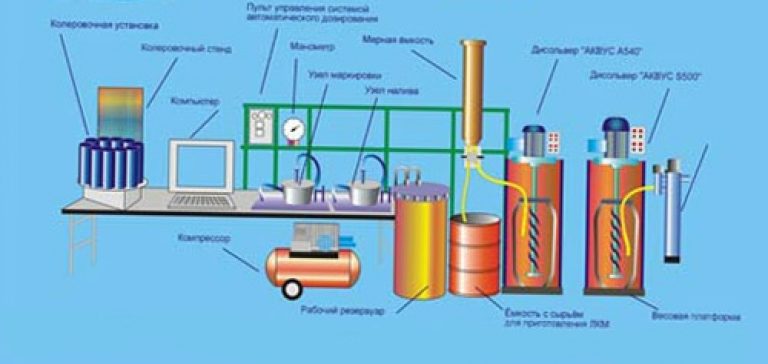

Production technology of water-free paint

The technological process of producing water-dispersion paint is the following algorithm of actions:

- pouring into water dissolver;

- the inclusion of the unit at minimum revolutions;

- loading other components in a certain sequence (fillers and pigments);

- adding dry components (titanium and chalk dioxide);

- dispersion of the solution for a certain period of time;

- filtration of the finished product;

- packing paints in consumer packaging.

In the process of dispersing, liquid and solid bodies are finely crushed. To increase productivity, beaded mills are used, a mixer of which brings the composition of paint to standard characteristics.

At the final stage, the finished paint is passed through the mesh filters and distinguishes into the container. It should be noted that the whole cycle of work on the manufacture of water-radiation paint should be held at ambient temperature not lower than +5 ° C.

Business Plan for the organization of the production of water-level paint

Requirements for production infrastructure:

- The area of \u200b\u200bthe manufacturing workshop is about 80 m 2.

- Temperature mode - not lower than +5 ° C.

- The presence of the necessary engineering and technical communications.

The cost of the technological line:

- dissolver - 200,000 rubles;

- beaded mill - 250,000 rubles;

- electronic scales - 6,000 rubles;

- hydraulic trolley - 7,000 rubles;

Total:463 000 rubles.

We will carry out the commodity analysis for the establishment of the production process.

For the production of 10 tons of finished products, the following components are needed:

- latex dispersion (65,000 rubles);

- defoamer (7 000 rubles);

- calcium carbonate (5,000 rubles);

- other additional materials (coalescent, thickener, titanium dioxide, etc. - 28 000 rubles);

- chalk (12 000 rubles);

- labels (6,000 rubles).

Total: 123 000 rubles.

For the year, this enterprise with declared production facilities is able to produce up to 120,000 kg. Water-emulsion paint. The annual costs of acquiring raw materials will be 1,476,000 rubles.

The personnel of the manufacturing workshop will consist of the following employees:

- head of production 15,000 rubles;

- working 8,000 rubles.

Total: 23 000 rubles.

Annual photo - 276,000 rubles.

Calculate the cost of 1 kg. Water-emulsion paint: 123,000 rubles / 10,000 kg. \u003d 12.3 rubles.

Equipment production capacity - 10,000 kg per month.

Production monthly costs make up:

- rent of production premises: 10,000 rubles;

- depreciation of the main equipment: 3 000 rubles;

- foundation for workers' remuneration: 23 000 rubles;

- payment of utilities: 5,000 rubles.

Thus, production costs per month (22 working days) are equal to 41,000 rubles, respectively - 492,000 rubles, respectively.

We estimate the economic efficiency of the project.

Annual cost \u003d Commodity cost + production costs \u003d 1,476,000 rubles. + 492 000 rub. \u003d 1 968 000 rub. / Year.

Wholesale price of paint It is 30 rubles / kg., And the monthly income, subject to complete implementation, will be 300,000 rubles, annual - 3,600,000 rubles.

Annual profit size: 3,600,000 rubles. - 1 968 000 rub. \u003d 1 632 000 rubles.

Net profit (minus the cost of equipment and fot) \u003d 1 632,000 rubles. - 463,000 rubles. - 276,000 rubles. \u003d 893 000 rubles.

Of course, in the first year of work, your enterprises, the size of net profit will be significantly understated due to the disposable acquisition of the production line. In the future, it may be gradually increasing production volumes, if there is appropriate demand.

We establish sales channels

The main indicator of product recognition should be its quality and affordable cost (at first). Thus, it is possible to establish itself as a conscientious manufacturer of high-quality water-dispersion paint, without inferior to expensive imported analogues. The use of imported raw materials will allow to achieve a similar result. Exceptions can be those fillers that are not inferior to foreign, but are much cheaper.

The undisputed advantage in the work can be the operational execution of large-volume applications - about 2 days. Therefore, soon the profit will cover all costs and production will become cost-effective.

The main sales channels is to establish cooperation with construction shops, supermarkets. It is also possible to conclude contracts with construction organizations that carry out services for the repair of apartments, offices and private houses, and restore work, etc. On the market it will not be superfluous to open a trading point for paint implementation, or even a corporate store with products. The accumulative discount system, various bonuses and promotional proposals will contribute to increasing sales.